What Is MIG Welding Utilized For?.

You have to know that welding needs pressure or warmth to be made use of to cause a resilient joint in between 2 different metal pieces. Relying on the part of the steel you need to bond or the specifications connected to weld coating, market professionals make use of various methods of welding to weld two steel pieces. Out of the methods that a person can make use of, two of the most prominent methods are MIG welding and TIG welding. If you want to understand even more concerning the MIG welding technique, we have you covered. Listed below enlisted are different elements of the MIG welding method that you need to recognize before using it..

MIG welding technique: All you require to know.

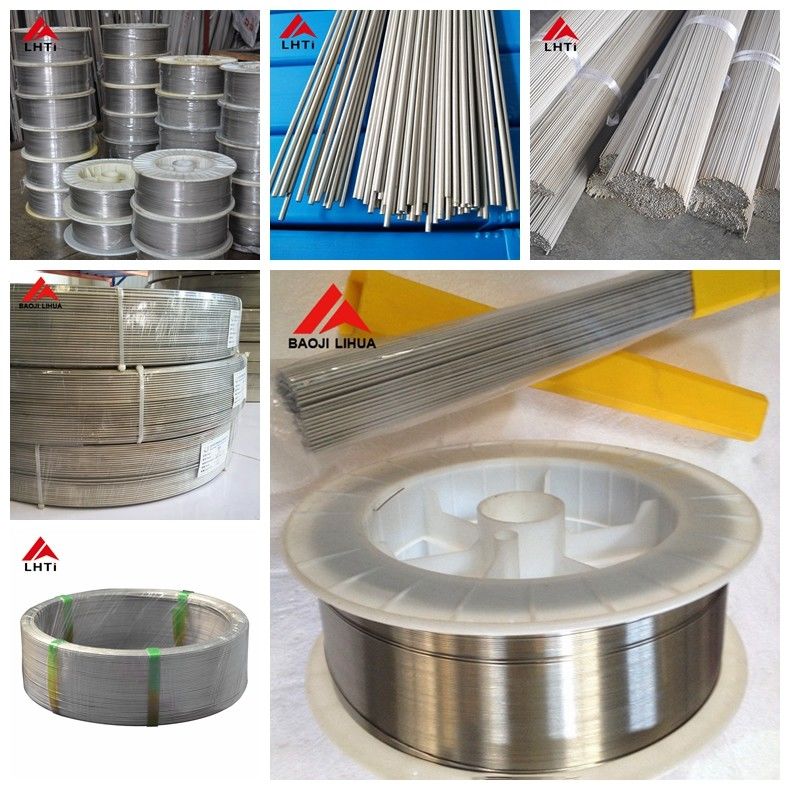

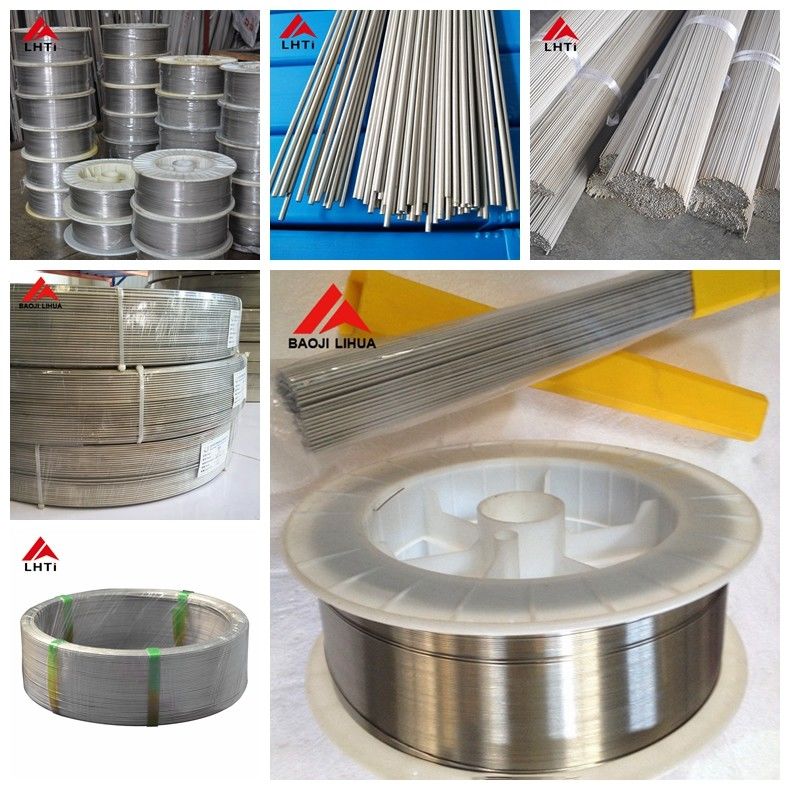

weldermetals.com welding technique runs under the given concept: an electric present melts the base materials by creating warm. Once the base materials cool, the products get joined as well as develop a strong joint. Contrasting all the benefits as well as negative aspects of all welding approaches, the MIG welding process is without a doubt the most effective one. MIG or metal inert gas welding is most suited for welding thick or larger products. ER4043 welding wire makes use of a consumable wire which works as both the filler material and also the electrode..

Contrasted to the various other kinds of welding methods, this technique is the fastest. It makes use of much less time to bond as well as includes fewer production expenses. Likewise, it doesn't generate any result and also for this reason is very easy to find out as well as produce welding outcomes. Additionally, the welding results done by this technique are strong, accurate, and also tidy..

Process Qualities.

This welding method is suitable for both thick as well as thin section products. A cable electrode and work item is taken and also in between the ends, an arc is struck. Now, both these points are melted to lead to a weld swimming pool. This cord attaches both ends of the two products works as both a filler product as well as heat resource for the welding process. The wire is run through a copper contact tube since copper acts as a great conductor of welding current and also passes it into the cable..

To safeguard the weld pool from the surrounding atmosphere, take the aid of protecting gas. Pass the gas throughout the nozzle. Currently, the gas you would select depends on the metal that you are welding, the application, the technique you are executing, as well as the kind of weld finish you want to attain..

The hands-on MIG welding procedure is commonly popularly called the semi-automatic approach. It's called so because the cable feed price and the length of the arc are determined by the resource of power. However, the traveling speed and the wire setting in the welding structure can be managed by the welder. If you are not going to do the procedure by hand, you can mechanise it. Yet it may still require some hands-on modifications. When no manual intervention is required, the welding procedure can be described automatic..

During the MIG welding process, the wire generally carries a favorable charge. It's linked to a source of power that provides a secure voltage. Generally, the cables that are chosen have a size ranging 0.6 as well as 1.6 mm. The wire feed speed mainly impacts the welding current since the burn-off rate of the cord is expected to come to be equal with the feed speed and create a state of balance..

Applications of the MIG welding process.

You would discover this approach extensively made use of in nearly every industry. This approach accounts for almost 50% of all the weld steel deposited. MIG welding technique is understood for its versatility and also convenience. It's additionally beneficial when it concerns the deposition rate of the procedure. However, you must keep in mind that this sort of approach is suitable when carried out for any kind of spraying metal. If you are applying it for any other usual steel, you need to have the required abilities to carry out the process properly..

Before you start this welding procedure, see to it you have taken sufficient safety measures. Use appropriate safety and security garments to protect on your own from potential fire mishaps that could take place at the same time. You have to put on basic security garments including leather gloves, fire immune jacket, long sleeves coat, leather shoes, safety helmet, and a turban or skull cap to cover your head from triggers.

MIG welding technique: All you require to know.

weldermetals.com welding technique runs under the given concept: an electric present melts the base materials by creating warm. Once the base materials cool, the products get joined as well as develop a strong joint. Contrasting all the benefits as well as negative aspects of all welding approaches, the MIG welding process is without a doubt the most effective one. MIG or metal inert gas welding is most suited for welding thick or larger products. ER4043 welding wire makes use of a consumable wire which works as both the filler material and also the electrode..

Contrasted to the various other kinds of welding methods, this technique is the fastest. It makes use of much less time to bond as well as includes fewer production expenses. Likewise, it doesn't generate any result and also for this reason is very easy to find out as well as produce welding outcomes. Additionally, the welding results done by this technique are strong, accurate, and also tidy..

Process Qualities.

This welding method is suitable for both thick as well as thin section products. A cable electrode and work item is taken and also in between the ends, an arc is struck. Now, both these points are melted to lead to a weld swimming pool. This cord attaches both ends of the two products works as both a filler product as well as heat resource for the welding process. The wire is run through a copper contact tube since copper acts as a great conductor of welding current and also passes it into the cable..

To safeguard the weld pool from the surrounding atmosphere, take the aid of protecting gas. Pass the gas throughout the nozzle. Currently, the gas you would select depends on the metal that you are welding, the application, the technique you are executing, as well as the kind of weld finish you want to attain..

The hands-on MIG welding procedure is commonly popularly called the semi-automatic approach. It's called so because the cable feed price and the length of the arc are determined by the resource of power. However, the traveling speed and the wire setting in the welding structure can be managed by the welder. If you are not going to do the procedure by hand, you can mechanise it. Yet it may still require some hands-on modifications. When no manual intervention is required, the welding procedure can be described automatic..

During the MIG welding process, the wire generally carries a favorable charge. It's linked to a source of power that provides a secure voltage. Generally, the cables that are chosen have a size ranging 0.6 as well as 1.6 mm. The wire feed speed mainly impacts the welding current since the burn-off rate of the cord is expected to come to be equal with the feed speed and create a state of balance..

Applications of the MIG welding process.

You would discover this approach extensively made use of in nearly every industry. This approach accounts for almost 50% of all the weld steel deposited. MIG welding technique is understood for its versatility and also convenience. It's additionally beneficial when it concerns the deposition rate of the procedure. However, you must keep in mind that this sort of approach is suitable when carried out for any kind of spraying metal. If you are applying it for any other usual steel, you need to have the required abilities to carry out the process properly..

Before you start this welding procedure, see to it you have taken sufficient safety measures. Use appropriate safety and security garments to protect on your own from potential fire mishaps that could take place at the same time. You have to put on basic security garments including leather gloves, fire immune jacket, long sleeves coat, leather shoes, safety helmet, and a turban or skull cap to cover your head from triggers.

Created at 2021-07-28 04:37

Back to posts

This post has no comments - be the first one!

UNDER MAINTENANCE